The manufacturing of clothes is a multi-step process that transforms raw materials into stylish, wearable garments. Whether for high fashion, casual wear, or sportswear, efficient clothing production requires precise planning, skilled labor, and advanced technology. From fabric selection to finishing touches, every step plays a crucial role in ensuring quality and durability.

Key Stages in Clothing Manufacturing

1. Design and Planning

Before production begins, fashion designers create sketches or digital designs, detailing fabric choices, colors, and patterns. These designs are turned into technical specifications, which guide manufacturers in producing samples for approval. manufacturing clothes

2. Fabric Sourcing and Processing

The choice of fabric determines the garment’s feel, appearance, and durability. Manufacturers source materials like cotton, polyester, silk, or blends from textile suppliers. Pre-treatment processes such as washing, dyeing, and printing enhance the fabric’s color and texture.

3. Pattern Making and Cutting

Pattern makers create templates based on the garment’s design, ensuring an accurate fit. These patterns are then used to cut fabric into individual pieces. Precision cutting is crucial to minimize waste and maintain uniformity. Automated cutting machines improve accuracy and speed.

4. Sewing and Stitching

Once the fabric is cut, skilled workers or automated machines stitch the pieces together. Different stitching techniques are used based on garment type—single-needle stitching for casual wear, overlock stitching for stretch fabrics, and reinforced seams for durability.

5. Quality Control and Inspection

Manufacturers conduct strict quality checks to ensure garments meet industry standards. Inspectors examine stitching, fabric strength, and design accuracy. Any defects are corrected before the garments proceed to the next stage.

6. Finishing Touches

Final adjustments such as ironing, embroidery, or adding labels take place before packaging. Some garments undergo special treatments like wrinkle resistance or water-proofing to enhance their functionality.

7. Packaging and Distribution

Once approved, the clothes are folded, tagged, and packed for shipment. Many manufacturers focus on eco-friendly packaging to reduce waste. The finished products are then sent to retailers, warehouses, or directly to consumers.

Types of Clothing Manufacturing

- Mass Production: Large-scale manufacturing for retail brands, ensuring affordability and efficiency.

- Custom Manufacturing: Smaller batches with specific designs, ideal for boutique brands.

- Sustainable Manufacturing: Uses organic fabrics, ethical labor practices, and eco-friendly production methods.

Trends Shaping Clothing Manufacturing

- Sustainable Fashion: Growing demand for ethical production and biodegradable fabrics.

- Automation & AI: Robotics and AI-powered machines enhance efficiency and reduce errors.

- On-Demand Production: Brands produce only what’s needed, reducing inventory waste.

Conclusion

The manufacturing of clothes is a dynamic process that blends craftsmanship with technology. From design to final packaging, each step ensures quality and efficiency. As sustainability and automation continue to evolve, the future of clothing manufacturing looks promising, offering better solutions for brands and consumers alike.

Joseph Mazzello Then & Now!

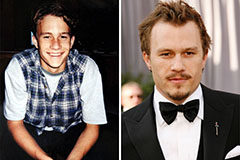

Joseph Mazzello Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!